About us

Main Grades

We produce a big range of different qualities with a maximum weight of a single piece of 50T.

20% of our production is dedicated to the grade 1.2311 (P20) for mould industry application.

| FORGED BLOCKS | FORGED ROUND BARS |

|---|---|

| UP TO 1000 MM THICKNESS | UP TO 1000 MM DIAMETER |

| 1.2311 (P20) | 1.2343 (H11) |

| 1.2312 | 1.2344 (H13) |

| 1.2738 (P20+Ni) | 1.2379 (D2) |

| 1.2738HH | C45E/R |

| 1.2083 (420C) | 42CrMo(S) 4 |

| 1.2083ESR | 40CrMnMo 7 |

| 1.2329 | 40CrMnMoS 8-6 |

| 1.2714 (6F3) | S355J2(J3) |

| 1.2343 (H11) | 18CrNiMo 7-6 |

| 1.2343ESR | 30CrNiMo 8 |

| 1.2344 (H13) | 39NiCrMo 3 |

| 1.2344ESR | 31CrMoV 9 |

| 1.2379 (D2) | 20MnCrS 5 |

| 1.1730 (C45U) | 18CrMoS 4 |

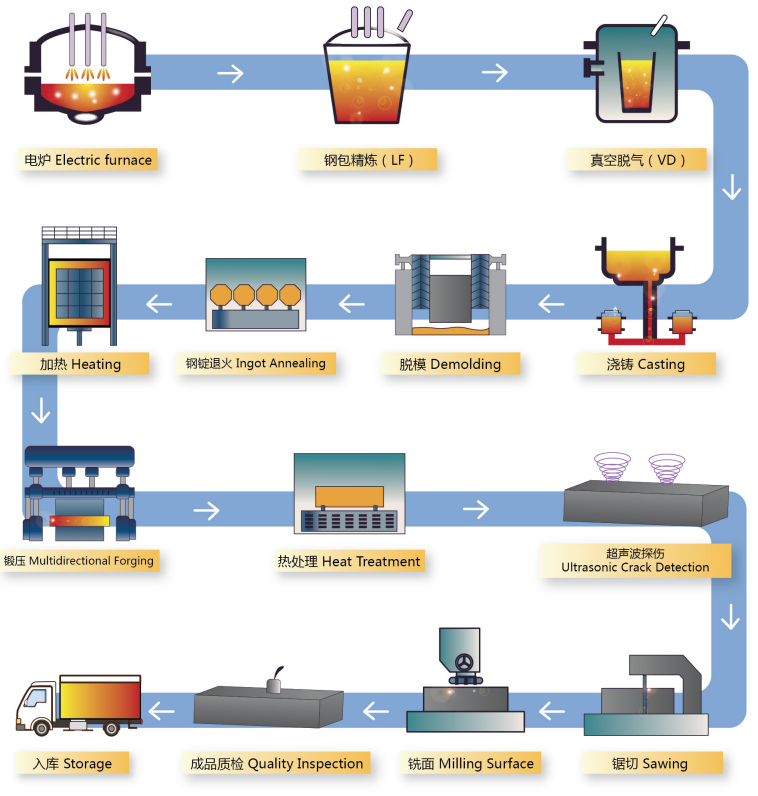

Our Manufacturing Process

Complete whole process from melting to final product :

Electric Furnace

LF

VD

Casting

Demolding

Ingot Annealing

Heating

Multidirectional Forging

Heat Treatment

Ultrasonic Crack Detection

Sawing

Milling Surface

Quality Inspection

Certification

We achieved ISO 9001 certification and we are currently applying for LR and DNV classification certification.